Installation

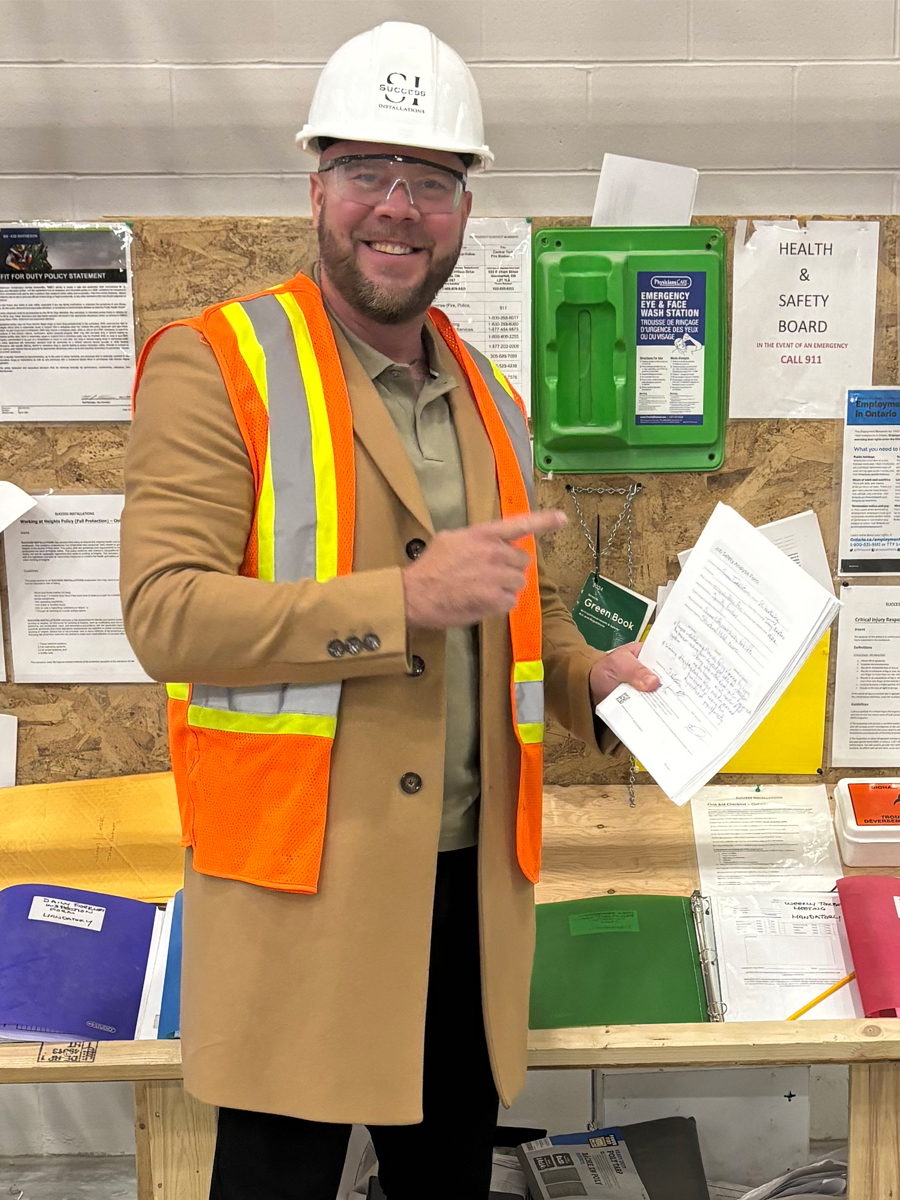

Meet Peter, an Industry Leader in Racking Installation

Peter, founder of Success Installations, has led the way in racking installations across North America. Known for his hands-on approach and commitment to excellence, he ensures that each project meets the highest standards in quality, safety, and efficiency.

-

Experienced

Decades of expertise in large-scale, complex racking installations. -

Professional Crew

Certified, skilled team dedicated to safe, precise installations. -

Direct Access

Work directly with Peter for honest, reliable service.

For tailored advice on your next project, contact Peter directly at (613) 790–9112 or submit a request for a callback.

Services

Installation Types

-

Structural Racking

Engineered with hot-rolled steel to handle heavy loads and withstand demanding warehouse conditions.

Features

- Ideal for high-capacity storage with minimal maintenance.

- Supports tall column heights for maximum vertical utilization.

- Easily integrates with existing warehouse layouts.

Best For

Warehouses requiring robust, long-lasting racking solutions for heavy or high-volume inventory.

-

Rack Buildings

Integrated racking structures that maximize vertical space, built directly into warehouse facilities.

Features

- Structural racking supports loads up to 50 ft high.

- Optimizes available space for diverse product sizes and types.

- Easily adaptable to future growth or changing inventory requirements.

Best For

Warehouses needing adaptable storage for varied products.

-

Selective Rollformed Racking

The most versatile and widely used racking system, allowing for easy access to individual pallets.

Features

- Structural racking supports loads up to 50 ft high.

- Reduces the need for additional warehouse buildings.

- Designed to withstand heavy-duty storage requirements.

Best For

Large-scale facilities requiring significant vertical storage.

-

Double Deep

Maximizes storage capacity by doubling pallets in a single row, perfect for high-density storage.

Features

- Maximizes storage density by placing pallets two rows deep.

- Increases storage capacity without expanding warehouse space.

- Reduces aisle space while maintaining efficient stock flow.

Best For

Facilities with fewer SKUs and high pallet volumes per SKU.

-

Shuttle Systems

The most versatile and widely used racking system, allowing for easy access to individual pallets.

Features

- Automates pallet movement to reduce manual labor and forklift travel.

- Provides high-density storage with efficient pallet retrieval.

- Improves inventory handling with faster loading and unloading.

Best For

High-volume facilities prioritizing automation and efficiency.

-

Storage Racking

Flexible racking options designed to accommodate varied storage needs and sizes.

Features

- Flexible configurations to fit various warehouse layouts and needs.

- Optimizes available space for diverse product sizes and types.

- Easily adaptable to future growth or changing inventory requirements.

Best For

Warehouses needing adaptable storage for varied products.

-

Mezzanine

The most versatile and widely used racking system, allowing for easy access to individual pallets.

Features

- Adds additional storage levels to maximize vertical space.

- Includes integrated safety features like handrails and stairs.

- Can be combined with conveyor systems for streamlined workflows.

Best For

Warehouses needing extra storage without increasing floor space.

-

Pick Towers

Multi-tier systems designed to streamline order picking and reduce travel time.

Features

- Incorporates shelving, conveyors, and walkways for efficient workflow.

- Maximizes vertical space with multiple picking levels.

- Customizable to accommodate various SKU sizes and pick rates.

Best For

High-volume distribution centers or eCommerce operations needing fast order fulfillment.

-

Pallet Flow

Gravity-driven racking system perfect for FIFO (First-In, First-Out) inventory management.

Features

- Inclined roller lanes automatically move pallets forward for easy retrieval.

- Simplifies replenishment and ensures efficient stock rotation.

- Maintains continuous product flow in high-turnover environments.

Best For

Warehouses focusing on perishable or time-sensitive goods that require strict FIFO handling.

-

Carton Flow

Roller-track racking for smaller, individual cartons or boxes to boost pick efficiency.

Features

- Angled rollers keep items at the picking face for quick access.

- Improves organization and reduces pick times.

- Adapts easily for changing carton sizes and SKUs.

Best For

High-volume picking operations handling small items or diverse SKUs.

-

Cantilever

Ideal for storing long, bulky items like lumber, pipes, and other oversized materials.a

Features

- Open-front design for easy storage and retrieval of long items.

- Adjustable arms to handle products of varying lengths and weights.

- Ideal for oversized, irregularly shaped, or bulky materials.

Best For

Facilities handling lumber, pipes, or other long, heavy items.

-

Drive-In

aximizes warehouse storage density by allowing forklifts to drive directly into the racking structure to place and retrieve pallets, significantly reducing aisle space.

Features

- Deep-lane storage with pallets stored multiple positions deep.

- Last-In, First-Out (LIFO) inventory management.

- Durable construction to withstand forklift operations.

- Ideal for high-density storage of similar products.

Best For

Facilities with large quantities of similar products, high-volume storage needs, or limited space.

-

Maintenance & Inspection

Extends the lifespan of racking systems with regular upkeep.

Features

- Extends the lifespan of racking systems with regular upkeep.

- Ensures compliance with safety standards and regulations.

- Minimizes downtime by preventing structural failures.

Best For

Warehouses focused on safety and long-term durability.

Start your project

Get in touch for customized, large-scale racking solutions

Call us at (613) 790–9112 for direct consultation.

Or, fill out our quick form and we’ll get back to you within 24 hours.